Today’s Theme: Key Features of Modern Automated Warehouse Systems

Robotics And AMRs: The Agile Backbone Of Automated Warehouses

Modern AMRs combine LiDAR, SLAM, and 3D cameras to dance through dynamic aisles, safely avoiding people and pallets. A Midwest distributor cut travel time by 38% after deploying AMRs that reroute in real time when congestion rises.

Robotics And AMRs: The Agile Backbone Of Automated Warehouses

By bringing totes to stationary operators, goods-to-person setups compress footsteps into seconds of productive picking. One fashion retailer increased lines picked per hour by half while reducing fatigue and training time for seasonal staff.

The Software Brain: WMS, WES, And WCS In Concert

Real-Time Orchestration Of Tasks

Modern WES prioritizes waves and waveless orders automatically, reallocating labor and robots to hotspots as demand pulses. One grocer saw backlog melt away when the system balanced replenishment and picking on the fly.

APIs And Data Harmony

Open APIs connect ERP, order channels, labor tools, and automation, reducing integration headaches and custom code. The result is faster change cycles and clearer digital thread visibility from click to dock door.

High-Density Storage: AS/RS, Shuttles, And Vertical Mastery

Shuttle Systems For Throughput Surges

Multi-level shuttles stage totes and cartons with millisecond accuracy. During a flash sale, a beauty e-commerce site maintained service levels by staging top sellers near dispatch for lightning-fast induction into picking.

Vertical Lift And Micro-Fulfillment

Vertical lift modules and compact micro-fulfillment nodes bring inventory closer to urban demand. A pharmacy network used them to promise two-hour pickup windows without adding a single new facility footprint.

Energy Efficiency By Design

Regenerative drives, smart acceleration, and sleep modes trim kilowatt-hours during off-peak windows. If sustainability sits high on your roadmap, tell us which metrics—energy intensity or carbon per order—matter most to your stakeholders.

Vision, Identification, And Sensing: Seeing Every Unit Clearly

High-speed cameras read labels at awkward angles and catch damaged packaging automatically. One electronics facility reduced return-related headaches by flagging suspect shipments before they left the dock, saving rework and goodwill.

Vision, Identification, And Sensing: Seeing Every Unit Clearly

RFID portals reconcile inbound and outbound counts without line-of-sight. A footwear brand finally killed its mystery shrinkage by tracking serialized pairs, aligning e-commerce promises with physical inventory confidence.

From order cycle time to picks per hour and dock-to-stock, actionable dashboards surface exceptions instead of burying teams in noise. Managers huddle around live boards during promotions, steering labor with confidence.

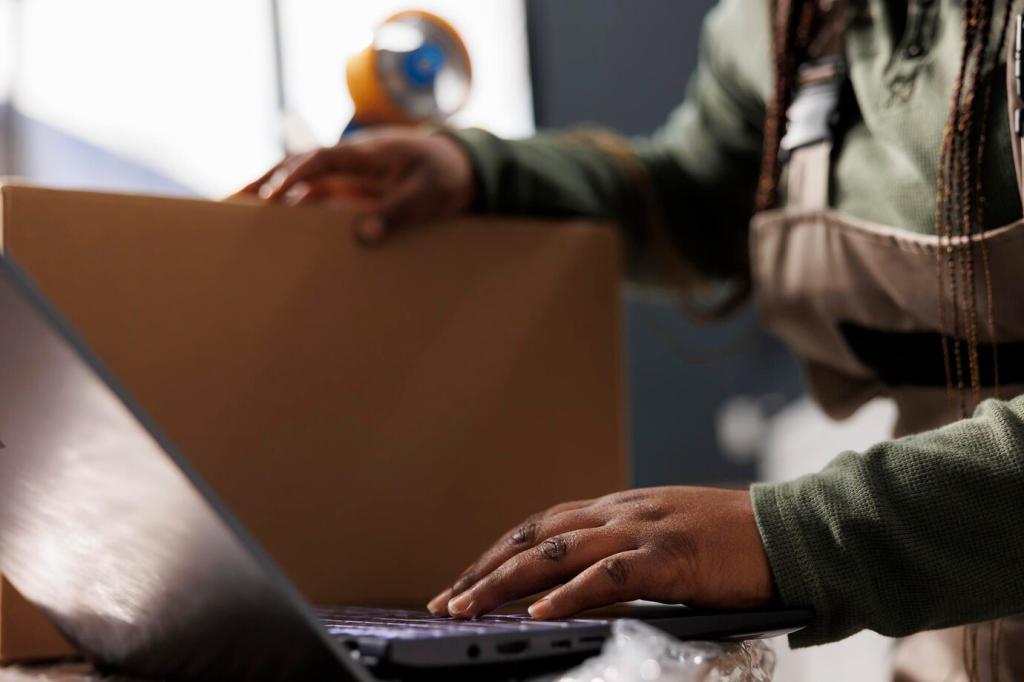

Human-Centered Design: Ergonomics, Training, And Change Readiness

Pick-to-light cues, height-adjustable stations, and lift assists reduce micro-injuries while speeding tasks. One operator joked they felt younger after peak, not older—an outcome worth broadcasting to skeptical teams.

Human-Centered Design: Ergonomics, Training, And Change Readiness

Clear icons, color cues, and context-aware prompts shrink training from weeks to days. Seasonal workers thrive when the system nudges next best actions instead of hiding them behind jargon-heavy screens.

Human-Centered Design: Ergonomics, Training, And Change Readiness

Pilot lanes, floor champions, and feedback loops build trust before go-live. Tell us your top training trick, and subscribe to get a practical checklist for onboarding new automation without losing momentum.